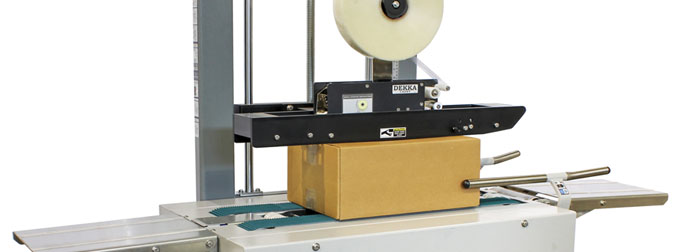

One decision that all manufacturers need to make when deciding on a packaging system is the adhesive. The 2 most popular types of adhesives for forming and sealing cases are Pressure Sensitive Tape and Hot Melt Glue. Today, we’ll go over some of the Pro’s and Con’s of each and what types of applications each one is more suited for.

Costs

The costs for hot melt glue and tape basically have opposite trajectories. Tape sealing equipment such as case formers and case sealers are usually significantly more affordable than hot melt options. However, hot melt is actually a less costly consumable and over time will be cheaper than tape.

Maintenance & Upkeep

For tape machines, the main equipment that will need to be maintained will be the tape head. Tape heads are relatively simple devices with minimal parts and can be easily be maintained by most technicians. However, most hot melt systems are more complex to maintain as the glue tanks and glue guns are rather complex and have greater chances of failure.

Applications

- One of the biggest reasons to use glue over tape is the versatility of glue. Hot melt is the adhesive of choice if you require a more custom seal such as RSC’s with gap flaps, trays, and others. With the growing adoption of corrugated saving packaging solutions, this has also led to the increasing growth of hot melt.

- Another issue to consider is the environment in which you are packaging. If you are packing in cold environment then hot melt may cool down too fast while a dusty environment may not be a good environment to use tape.