In the last 2 postings, we went over belts and flap folding on a case sealer. This week we are going to go over some of the less tangible issues when choosing a case sealer such as design, service support etc.

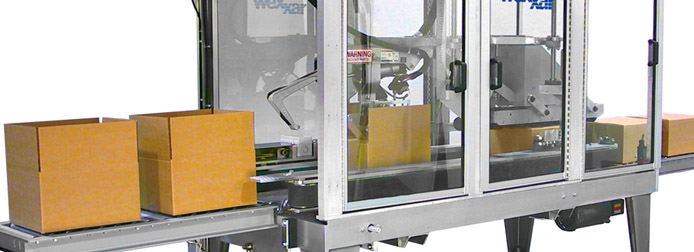

As case sealers are relatively simple, designs for this type of machine are very simple and very similar between different brands. Where you will notice the difference is whether the company has put in effort to make the experience easier for the operator(s). For example, Wexxar/BEL case sealers feature on machines instructional guides as well as color coded size change labels to help make size changes as quick and precise as possible.

Another factor to pay attention to is where the machine is made. This will often give you an idea of how well made or durable the machine is. Typically machines made in China or Asia are less robust compared to those of North America. However, perhaps the even bigger issue in regards to this is whether you will get the technical support needed if and when your machines goes down. Imagine having to wait weeks for a small part that is shipping from China or Italy while your machine is down and need to slow or even shut down your entire line.