When looking to make any purchase or investment in your company, one of the first things you should be asking is “What’s the ROI? What’s my Return on Investment?” Taking a look at the ROI will tell you what kind of impact the purchase will have on your business and how fast you can recover that money and how much money you are constantly saving in the future. In this post, we’ll discuss how to properly calculate ROI when looking to automate your packaging line.

First of all, you should take a look at the costs associated with your current packaging line. How many workers are on the line? How much are they paid? Do they usually work overtime? What about benefits ? This information is good to know just from an operational standpoint but when looking to change from a manual hand pack line to an automatic or semi-automatic line, it allows you to easily compare your current solution with the proposed solution.

The next step is to look at the operational costs of the automated solution. How many operators are required with the packaging equipment? What’s the cost of operation (air and power)? How often is machine service required? By comparing the differences in operational costs (usually the cost of automation is lower or it isn’t even worth your time) per year or per month, you will understand how many months or years it will take for you to make the money back.

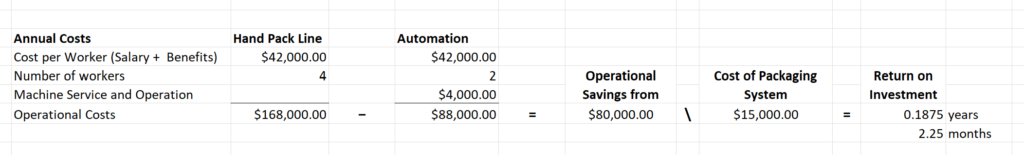

Below is a very simple example:

The above example tells us that it will take the customer 0.1875 years or 2.25 months to recover his money from purchasing the system which seems like a very good investment. After making back the money to purchase the system, any additional operational savings become profit for the company.