By Sander Smith

With Christmas only a few days away, packages of all shapes and sizes are crisscrossing the country in a mad dash to land on doorsteps by December 25. As people open their packages, the product inside often is not the only surprise they find as the enormous size of the box itself leaves many astonished. As consumers become more environmentally conscious about the brands and products they support, seeing packages arrive that are not right-sized for their order leads to bewilderment with why the box is so large. Some have even taken to the internet to share their frustrations. The subreddit EgregiousPackaging on Reddit is filled with photos from baffled readers showing oversized boxes and the products they carried. One such post shows an image of a very large rectangular box with the caption “This box was used to ship two windshield wipers.”

How does this happen in the first place? Why does it seem that some products are shipped in boxes that are clearly oversized? The likely answer is the person responsible for packing a product is selecting a box that is easiest for him or her to use. There is often no set direction or instruction on which box to use for a specific product. They are free to select whatever size box to package the product, and if it is easier to keep grabbing the same sized for even smaller product orders, that tends to be the path they follow. This is how, for example, a four-pack of AAA batteries can arrive in a large box.

The financial impact of selecting an oversized box can quickly add up for companies. For starters, a larger box contains more material to manufacture than a smaller box. Using larger boxes takes more void fill to pack the box, and also elevates the package into a higher dimensional shipping weight class. When you factor in additional corrugate, void fill, and larger dimensional shipping weight, the cost to ship that package has needlessly gone up. Although that increase may be small when comparing one package to another, those costs collectively begin to rise quite substantially when you look at how many packages you are shipping per week, per month, and even per year. This does not even include the costs associated with returned product or customer loss if an item is damaged from shaking around in an extra-large box.

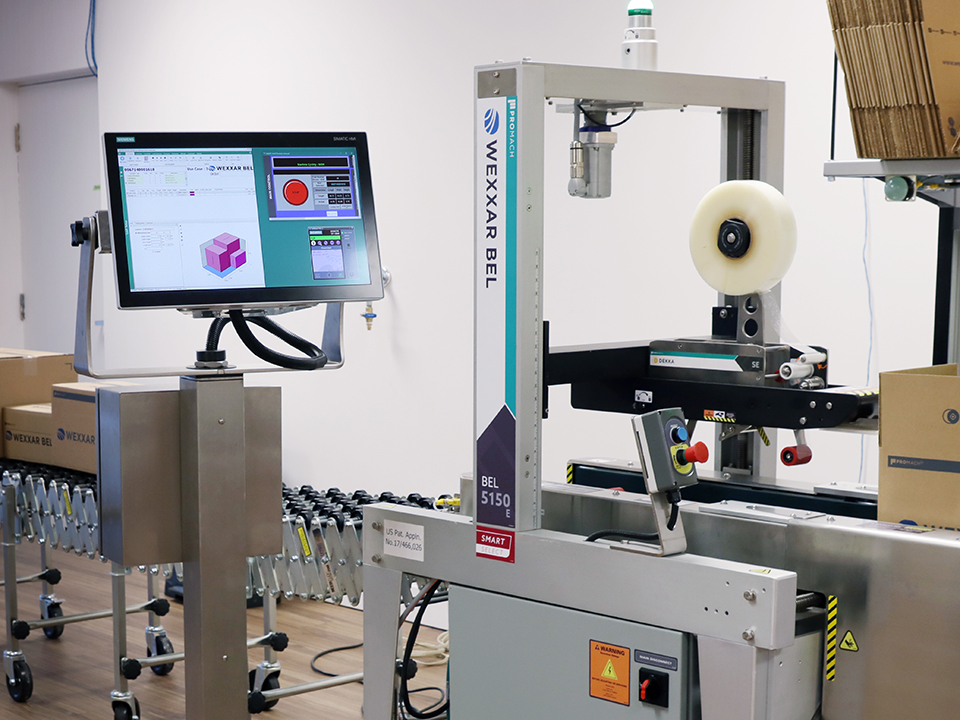

The key to keeping shipping costs down is right sizing the container for the order. There is no good reason why a pack of batteries needs to be packaged in a bulky, oversized container. Rather, pack and seal systems today can collaborate with a company’s ERP (Enterprise Resource Planning) or e-commerce systems to identify products and recommend the right sized container for each specific order. This level of intuitive technology is engineered into Wexxar Bel’s 5150E Semi-Automatic Form, Pack & Seal Machine, which is an all-in-one form, pack, and seal system designed for e-commerce.

The system works by first identifying all products for each order, then directing the operator to pick the correct case blank to ensure the right case is used. The power behind this technology is Wexxar Bel’s Smart Select software, which reviews the contents of each order and recommends the right-sized case for packing. When an order arrives at the case packer, it directs the operator to the box best suited for that order. The HMI even provides a 3D image of how the products should be packed into the box. From there, the operator selects the blank, loads it into the case former, and then packs and verifies the contents, case is automatically sealed and ready for shipping. The 5150E has the capacity to run up to 30 different box sizes, and has the flexibility to handle more to accommodate future growth.

By automating your case packing operations, you eliminate the guesswork of employees choosing a box; you’ve taken the decision out of their hands and have replaced it with a system that identifies the right sized box to use, and it is correct 100 percent of the time.

In the long run adding this level of automation will reduce your corrugate, dunnage, and shipping costs, while also providing a more secure environment for products during transport. But perhaps most importantly, it passes the eye test with consumers – and that’s something to brag about online.

Sander Smith is the product manager for Wexxar Bel, a ProMach brand. He can be reached at Sander.Smith@promachbuilt.com; https://www.wexxar.com/